Home & Decor Blogs: DIY, Interior Design & Lifestyle Ideas

5 Most Common HVAC Problems and How Technicians Fix Them

The focus now is on repairs, which are dominating the industry. The costs of replacements have jumped by about 50 percent, when compared with 2019 — what had been $6,000 to $8,000 is now running between $11,500 and $14,000. With such a surge in cost, the most common choice is to repair rather than replace – these five issues are top of every technician’s service list.

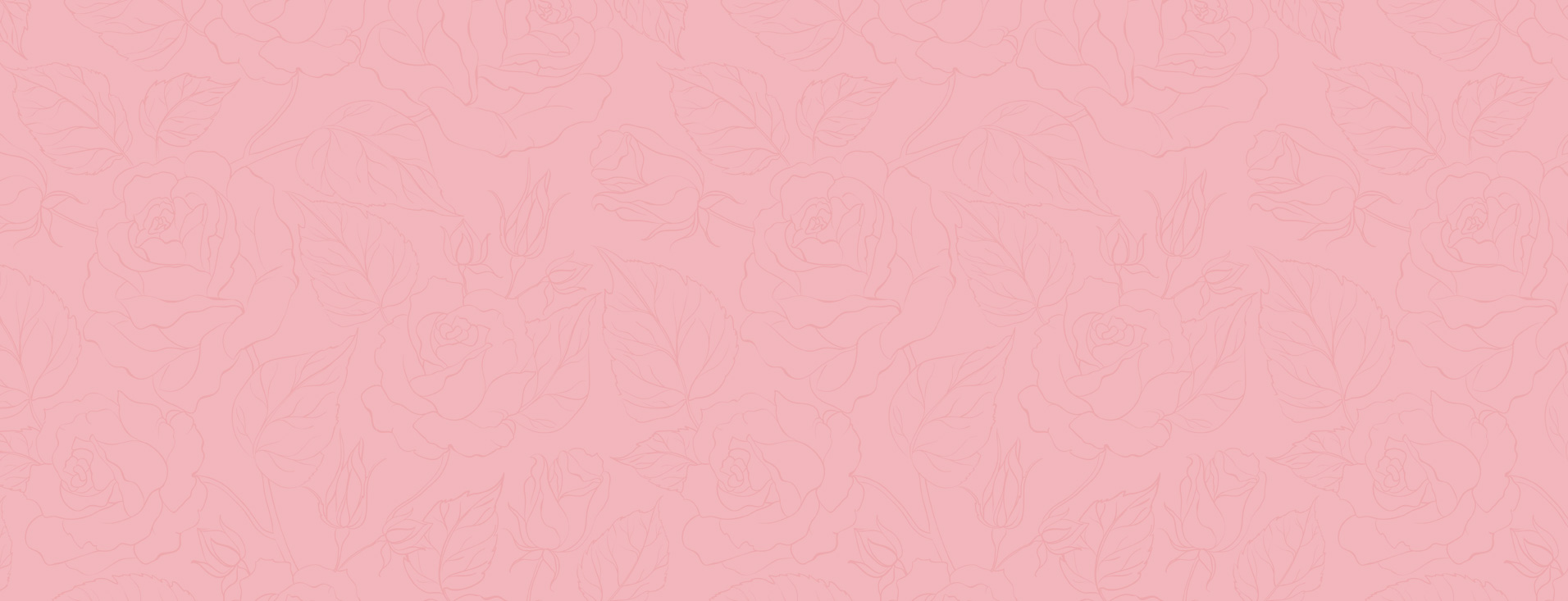

1. Dirty Air Filters

This is the No.1 reason HVAC systems don’t last. A block in your filter causes the rest of your system to work harder to push air through and that stress affects all the parts — blower motors overheat, evaporator coils freeze up, leaving you with energy bills that climb anywhere from 5% to 15%, says the US Department of Energy.

Signs you’ve got a filter problem:

- Weak airflow from vents

- System running constantly but never hitting the right temperature

- Dust building up around registers faster than usual

The fix is straightforward. Technicians inspect the filter (a shocking 29% of homeowners never change theirs), replace it, and check the ductwork for debris or loose connections. If the coils have already accumulated grime, they’ll clean those too. The whole job typically runs $75 to $150, and it prevents breakdowns that would cost ten times that.

How often should you change it? Most filters need swapping every 30 to 90 days depending on the type. Fiberglass filters need monthly attention. Pleated ones can stretch to 90 days. Got pets or allergies? Check it more often.

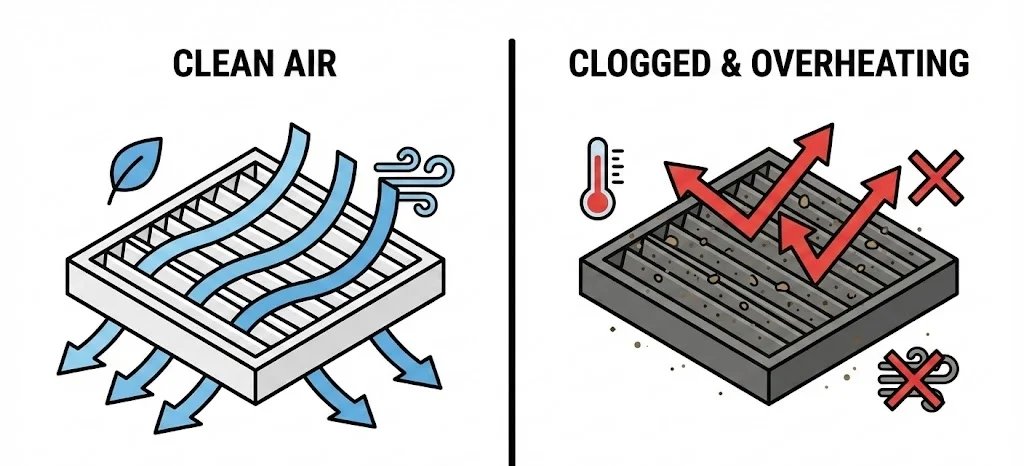

2. Thermostat Malfunctions

Your thermostat is what tells the system when to run and when to stop. When it sends incorrect signals — or no signal at all — you’re left with rooms that won’t cool, systems that short-cycle and shut down too frequently, and equipment running incessantly without reaching the desired temperature.

Common culprits:

- Dead batteries (the most overlooked cause)

- Bad placement near windows, exterior walls, or heating vents

- Dust buildup inside the unit

- Worn wiring between the thermostat and equipment

Technicians first check voltage with a multimeter and wiring continuity. If the thermostat is located where sunlight beats down on it, for example, or drafts disturb its readings, they will either move it or advise that you do so. The contacts get dirty and once you clean them, things work again. Other times, it may be worth upgrading to a programmable or smart thermostat (such as Nest, Ecobee) — the proper working of a thermostat can decrease system wear by 20 and 30 percent and save energy.

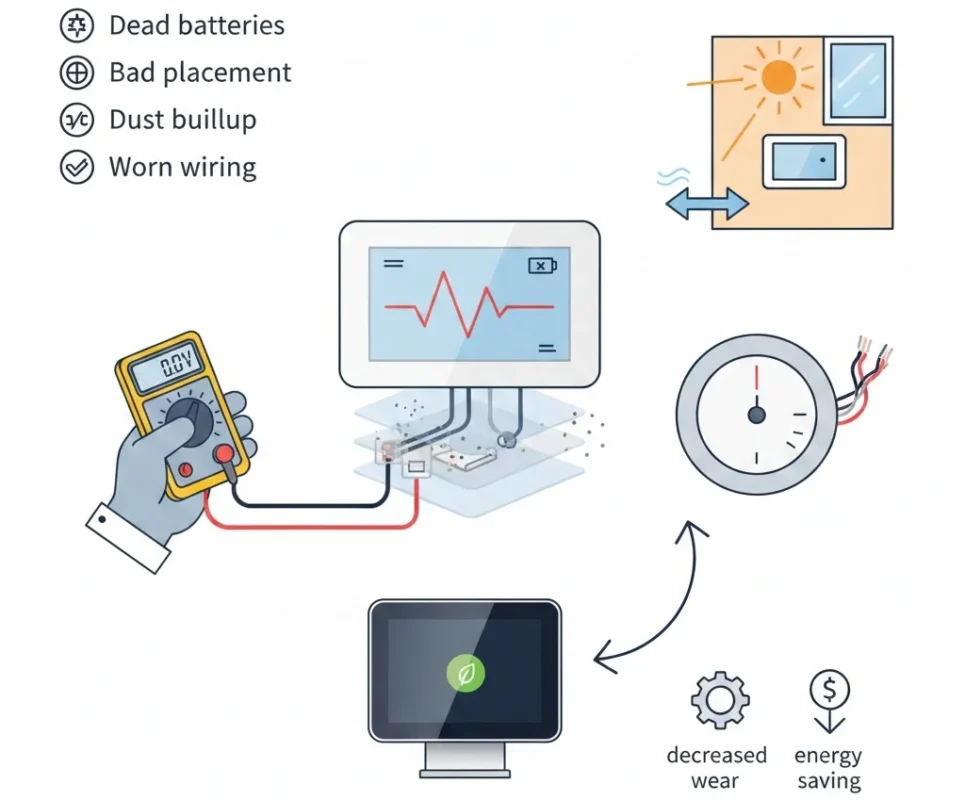

3. Refrigerant Leaks

If you are blowing warm air from your AC or have seen that ice is beginning to form on the coils, a refrigerant leak is likely in play. This is a big one — lose 10% of your refrigerant and drop the system’s efficiency by 20%, which will, sooner or later, kill the compressor.

What causes leaks? Corrosion, vibration wear, manufacturing fault or simply old age. Evaporator coil leaks generally appear around 8 to 15 years of use.

Leak is found using electronic detector, uv dye test or nitrogen pressure. Once they locate the source, they seal or replace the offending component, evacuate and pressure tests the system, then recharge it back to manufacturer specs. The HVAC repair costs between $200 and $1,500 depending on severity and location — evaporator coil leaks are the most expensive.

Important notice: the installation of any component or system (and its individual components) should only be performed by licensed and trained professionals with the proper equipment and background in handling refrigerants- epa certification is a plus. This is not a do-it-yourself job, in fact it’s illegal to try and do it yourself if you are not properly credentialed.

Important notice: the installation of any component or system (and its individual components) should only be performed by licensed and trained professionals with the proper equipment and background in handling refrigerants- epa certification is a plus. This is not a do-it-yourself job, in fact it’s illegal to try and do it yourself if you are not properly credentialed.

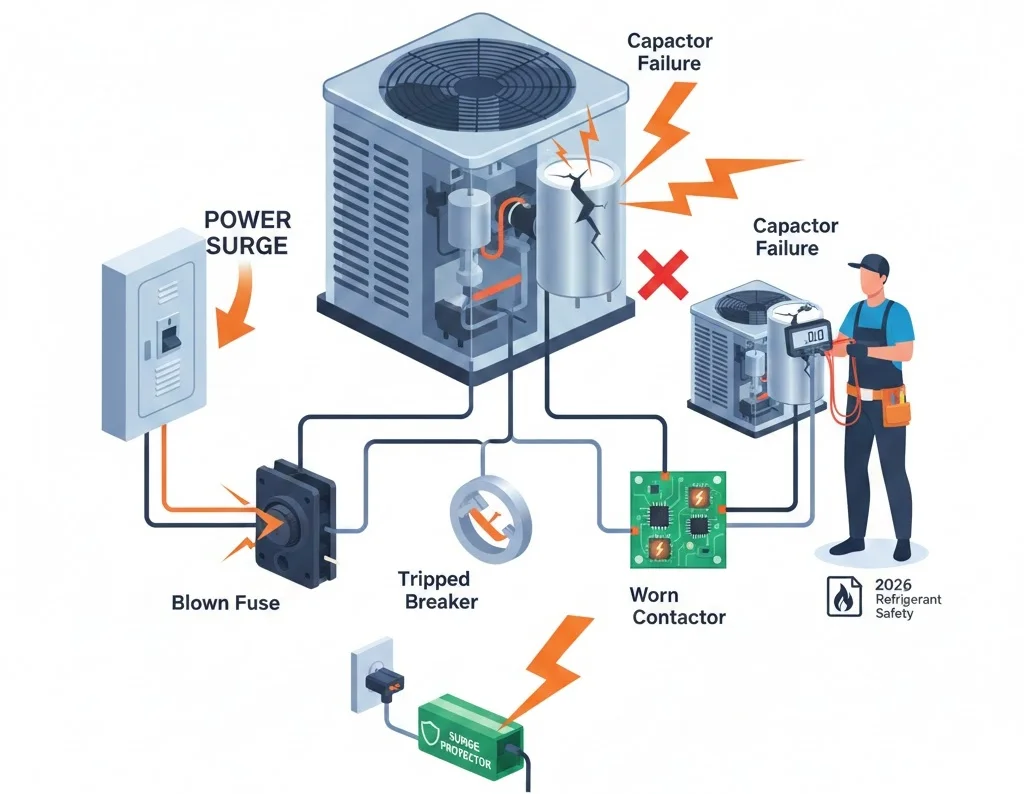

4. Electrical and Capacitor Failures

Capacitors start your system’s motors. When they fail, the unit either won’t turn on or makes a humming sound while nothing actually runs. This accounts for a significant chunk of summer breakdown calls — it’s the kind of failure that happens suddenly and stops everything.

What goes wrong:

- Capacitor failure (most common — usually from heat stress or age)

- Blown fuses or tripped breakers from power surges

- Worn contactors and relays

- Faulty control boards

Technicians also check capacitors with capacitance meters and test amperage on compressors. Replacing a capacitor is low-cost: the part itself costs $10 to $50, depending on the make and model of your A/C unit, and it only takes a few minutes to complete. Worst case scenario is compressor failure, which will cost you between $1,000 and $2,500 when all is said and done with a system flush and recharge.

2026 note: New appliances operating with A2L refrigerants (R-454B, R-32) are equipped with new electrical components which have been designed to reduce the number of ignition sources. If your system is relatively new, chances are it comes with these safety features: External refrigerant detection systems can shut a unit down upon detecting a leak and turn on ventilation.

Surge protectors can prevent these failures. Great investment if you don’t already have one on your hvac equipment.

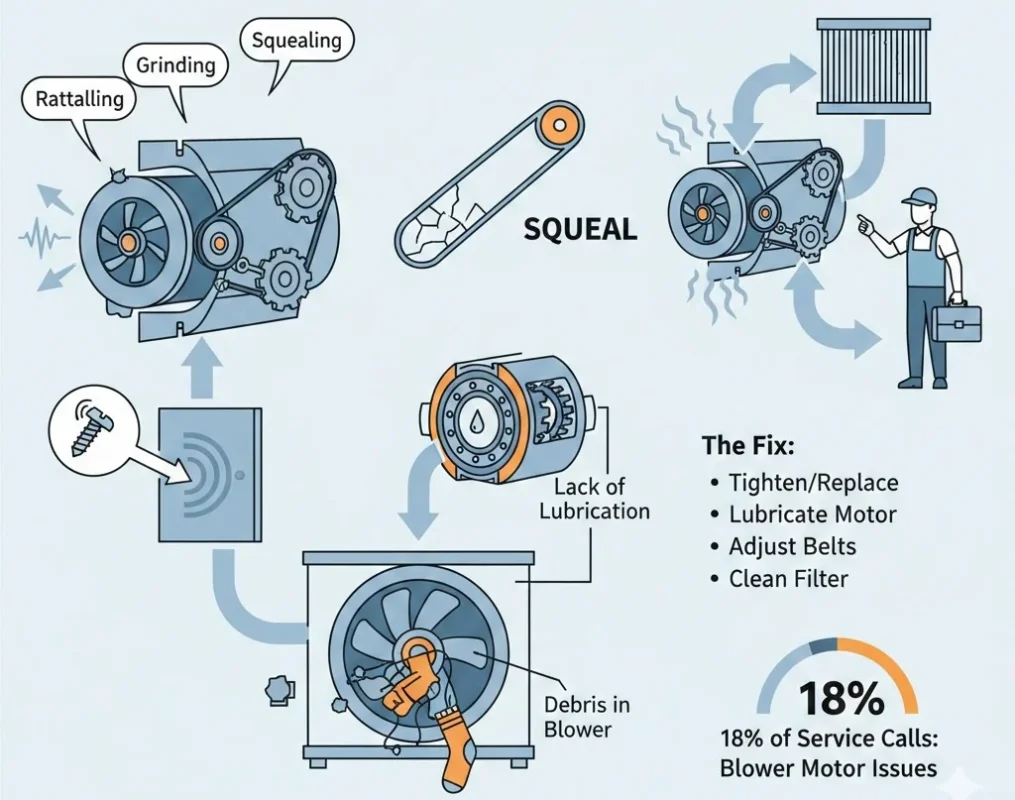

5. Unusual Noises and Mechanical Wear

Rattling, grinding, squealing, or buzzing sounds mean something mechanical is failing. Loose components, worn belts, bearing issues in the motor — any of these can create noise and reduce efficiency. Ignoring them tends to escalate into bigger (more expensive) problems.

What technicians look for:

- Loose screws and panels causing rattling

- Worn fan belts that squeal or slip

- Motor bearings grinding from lack of lubrication

- Debris caught in the blower assembly

The fix involves tightening or replacing worn pieces, lubricating motors, and adjusting belts. If airflow problems caused the mechanical stress in the first place (often from — you guessed it — dirty filters), they’ll address that root cause too.

About 18% of service calls involve blower motor issues specifically. Catching noise problems early prevents full motor failure, which is a much costlier repair.

What This Costs in 2026

The average repair bill can fall somewhere between $150 to $450 for most jobs, though more complicated work quickly climbs into the thousands. Full system replacement is now about $11,500 to $14,100 for a typical home — in line with 2025 prices when adjusted for material cost increases (3% to 6%) and the refrigerant transition.

The rule of thumb: if the cost to repair or replace is more than 50% of the replacement cost, or you can multiply the repair cost by your AC’s age and get a number higher than $5,000, it starts to make financial sense.

Keeping Things Running

| Task | Frequency | Why It Matters |

|---|---|---|

| Change air filters | Every 1-3 months | Prevents 80% of airflow-related failures, cuts energy use 5-15% |

| Clean coils and drains | Annually | Stops freezing and leaks, extends compressor life |

| Check refrigerant and electrical | Twice yearly (professional inspection) | Catches 90% of failures before they happen |

| Test thermostat and ducts | Seasonally | Ensures even heating/cooling, reduces energy 10-20% |

Most problems here start small and get expensive because nobody catches them early. Regular maintenance — even just changing the filter on schedule — prevents the majority of emergency calls.

FAQs

Dirty air filters. They restrict airflow, force components to work harder, and cause cascading failures throughout the system. Changing your filter regularly prevents most breakdowns.

Most repairs run $150 to $450. Complex jobs involving compressors or coils can hit $1,000 to $2,500. Full system replacement averages $11,500 to $14,100.

Signs include warm air from vents, ice on the evaporator coil, hissing sounds near the unit, and higher-than-normal energy bills. A technician can confirm with pressure testing or electronic leak detection.

If repair costs exceed 50% of replacement cost, or if the repair cost multiplied by the system’s age exceeds $5,000, replacement usually makes more sense. Systems over 15 years old with major problems are typically better replaced.

The industry is transitioning from R-410A to lower-GWP refrigerants like R-454B (A2L class). New systems manufactured after January 2025 use these newer refrigerants. Existing R-410A systems can still be serviced and repaired — there’s no end date for that.

Twice yearly — once before cooling season, once before heating season. Professional maintenance catches small problems before they become expensive repairs.