Home & Decor Blogs: DIY, Interior Design & Lifestyle Ideas

Construction Trash Chute Systems for Efficient Debris Removal and Site Safety

Construction Trash Chute Systems for Efficient Debris Removal and Site Safety might not sound glamorous, but they’re the quiet MVPs of a tidy, productive site. Instead of lugging broken drywall down stairs, blocking corridors, or “temporarily” piling waste in walkways (we’ve all been there), a properly designed chute lets gravity do the heavy lifting while your crew stays focused on real work.

Efficient waste management is a cornerstone of successful construction projects. Proper handling and disposal of construction debris not only keeps job sites safe and organized but also ensures projects run smoothly without unnecessary delays. One of the most effective tools in every contractor’s arsenal is a reliable construction trash chute system. This comprehensive guide will explore everything about construction trash chute systems from types and materials to installation, safety tips, and maintenance. By the end, readers will fully understand how to select and utilize a construction trash chute system that meets their project’s demands, improving safety, compliance, and operational efficiency.

Understand Construction Trash Chute Systems

Construction trash chute systems are designed to transport waste materials from elevated work areas to ground-level disposal zones efficiently and safely. Often made from durable plastic or steel, these chute systems create an enclosed passageway, directing trash away from workspaces and minimizing the risks of debris falling uncontrollably.

Debris chutes are indispensable on multi story building projects or any construction sites generating large volumes of waste, such as roofing scraps, drywall pieces, demolition debris, and general rubbish. Using debris chutes reduces manual labor, minimizes workplace hazards, and streamlines the trash removal process.

Because every construction site is different, choosing the right chute layout and materials ensures maximum performance. For example, a roofing debris chute can handle shingles and insulation efficiently without clogging, while a heavy duty construction debris chute is better suited for concrete, brick, and demolition waste. Many contractors underestimate how much time is lost hauling trash manually trash chutes and construction waste chutes solve this problem while improving compliance with safety regulations.

Types of Construction Chute Systems

- Plastic (HDPE) chutes: Constructed from high density polyethylene, these chutes are lightweight, impact-resistant, and cost-effective. They are best for residential or mid-sized projects involving lighter waste, such as drywall, roofing shingles, and wood. Some are UV stabilized for weather resistance.

- Heavy-duty/Reinforced plastic chutes: These systems use reinforced polyethylene with thicker walls to handle more demanding waste. They are suitable for medium-to-large projects and can withstand concrete, brick, and other heavy, abrasive materials.

- Steel chutes: Used for high rise or industrial projects, steel chutes offer maximum durability and fire resistance. They can withstand heavy, abrasive waste better than plastic but are also heavier and more expensive. Stainless steel is a robust, corrosion resistant option often found in permanent installations.

- Rubber chutes: Offering excellent noise reduction and flexibility, rubber chutes are often preferred for demolition jobs. They absorb the impact and vibration of irregular or oddly shaped debris.

Features That Set Superior Construction Trash Chutes

High-quality construction trash chute systems include features designed to maximize safety, durability, and ease of use:

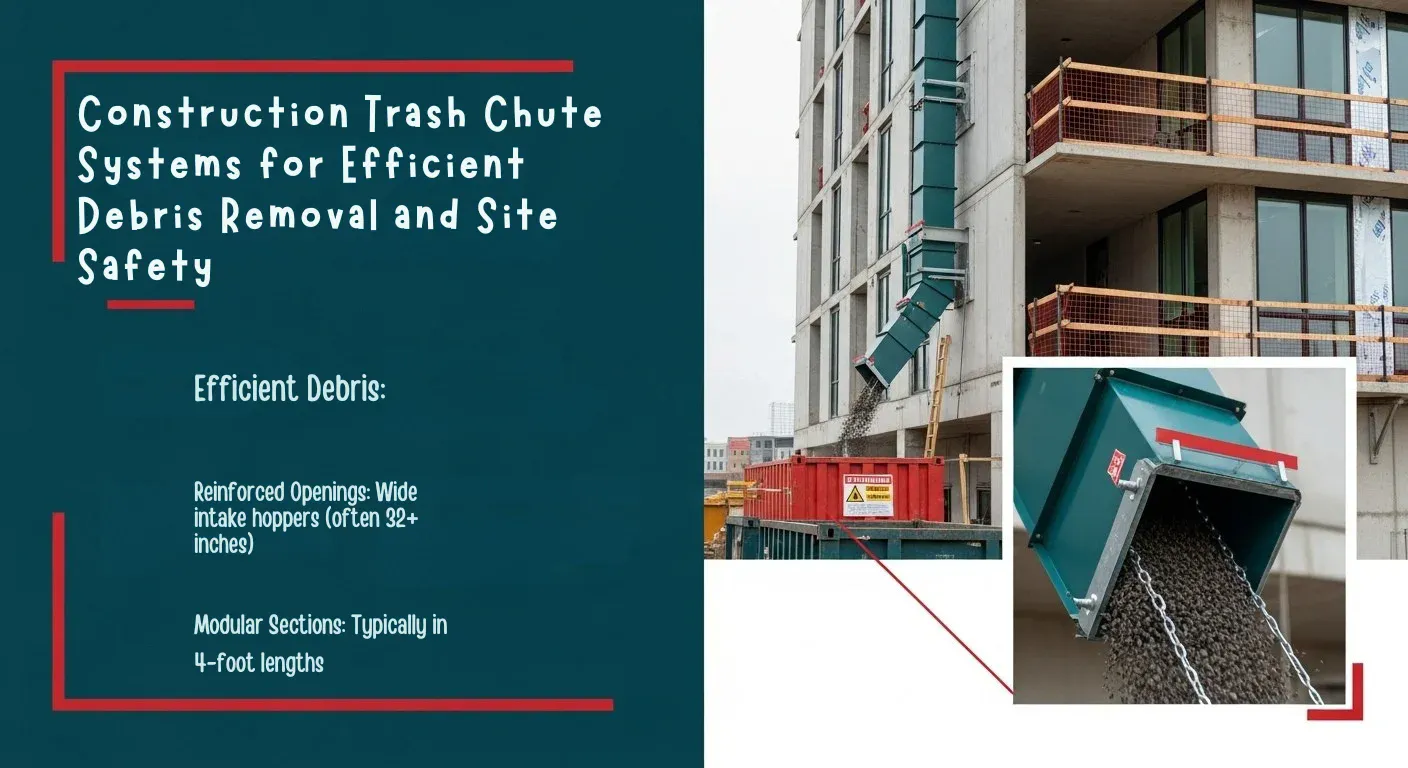

- Modular Sections: Typically in 4-foot lengths, these allow customization of chute height to fit buildings precisely.

- Reinforced Openings: Wide intake hoppers (often 32+ inches) provide easy loading access and prevent material jams.

- Safety Gates: Lockable doors at multiple levels prevent accidental falls or debris scattering.

- Durability Enhancements: Heat-treated galvanized chains, protective liners, and reinforced steel supports extend service life.

- Compatibility with Winches: Manual or electric winches facilitate raising, lowering, and relocating chute sections quickly.

For roofing debris chute systems or multi floor construction waste chute setups, these features aren’t just conveniences they’re essential for keeping the site safe and efficient. A well-designed garbage chute or trash chute can handle different materials without frequent jams, which minimizes downtime. Some advanced systems even integrate dust gaiters or liners to reduce mess and extend the lifespan of each chute section.

Benefits of Using Construction Trash Chute Systems

Investing in a construction trash chute system yields multiple advantages:

- Improved Safety: Enclosed chutes significantly reduce the risk of falling debris injuring workers or passersby.

- Efficiency Boost: Debris moves quickly and safely from upper floors to disposal, reducing time spent handling trash.

- Compliance with Regulations: OSHA mandates chutes for waste disposal from heights over 20 feet, helping sites avoid fines.

- Site Cleanliness: Controlled waste flow prevents scattering of dust and litter, creating a cleaner, professional environment.

- Cost-Effectiveness: Durable systems lower long-term waste disposal costs by minimizing plumbing damage and maintenance.

How to Choose the Right Construction Trash Chute System

Selecting a trash chute system should factor in:

- Project Scale: Larger projects may require more sections and wider diameters (26–33 inches).

- Debris Types: Heavy demolition debris demands sturdier materials and thicker chute walls.

- Installation Conditions: Access points, building height, and available anchors affect chute configuration.

- Budget: Options range from basic plastic chutes to reinforced systems with advanced features.

- Safety Requirements: Ensure compliance with local standards, including secure attachments and guardrails.

Installation Best Practices

Proper installation is essential for safe operation:

- Secure chutes firmly to scaffolding, walls, or roof ledges using manufacturer-recommended anchors.

- Maintain vertical alignment to avoid blockages; minimize bends in the chute column.

- Position safety gates on every usable floor opening for controlled access.

- Clearly mark landing areas and keep bystanders away from downpipe collection zones.

- Use winches for lifting heavy chute segments safely.

- Follow OSHA guidelines for chute use, including secure attachments and gate closures.

An electric winch can significantly reduce labor when hoisting multiple chute sections into place, especially on taller structures. Construction chutes should be inspected immediately after installation to ensure chains and supports are tight. Roofing chutes, in particular, need secure edge attachments to handle repeated use and changing load patterns. A stable rubbish chute system keeps the site running smoothly and minimizes the chance of costly accidents.

Maintenance and Safety Checks

Regular checks extend chute life and enhance safety:

- Inspect sections daily for cracks, wear, or loosened fasteners.

- Replace damaged components to prevent accidents and maintain debris flow.

- Lubricate moving parts like gates to ensure smooth functioning.

- Clean chutes to remove buildup and debris residues.

- Store sections properly when not in use to avoid warping.

For construction waste chute systems, proactive maintenance is critical. Dust buildup, sharp debris, or bent chains can quickly affect performance. Plastic chutes can be rinsed and dried easily, while steel demolition chutes might require more frequent inspections due to heavier loads. Regular upkeep ensures your trash chutes stay safe and functional throughout the entire project timeline.

Complementary Waste Solutions Dumpster Bags and Containers

Trash chutes channel waste to collection points often equipped with dumpster bags or bins tailored to the project size and debris volume. Properly sized, heavy-duty dumpster bags resist punctures and spills, ensuring safe containment. Strategically placing dumpsters and bags reduces overflow, keeps the site tidy, and simplifies waste hauling.

Pairing a rubbish chute system with strong dumpster bags ensures that materials don’t scatter around the collection area. Contractors often underestimate how much debris can accumulate in a single day. Matching the chute capacity with dumpster bag capacity prevents blockages and supports a seamless workflow, especially on large roofing or demolition projects.

Specialized Trash Chutes for Roofing and Demolition

Roofing projects benefit from lightweight, flat or slightly angled chutes designed to manage shingles, insulation, and nails efficiently. Demolition applications require reinforced chutes capable of absorbing impact from large and abrasive debris pieces, often featuring protective liners and heavy gauges.

These specialized solutions make roofing chutes and demolition chutes indispensable on modern sites. They address unique challenges roofing debris chute setups reduce the risk of flying nails and broken shingles, while heavy demolition chutes can withstand bricks, concrete, and rebar without failing. By selecting the right combination of chute types, contractors can keep their sites safer and cleaner from start to finish.

The Role of Electric Winches

Electric winches revolutionize chute systems by speeding up installation and removal while reducing manual labor injuries. They allow easy adjustment of chute height to match work floors and support sections during moves or storage.

Winches are especially useful for tall buildings and projects where chutes need to be frequently relocated. Whether working with trash chutes for construction, plastic chutes, or heavier steel demolition chutes, an electric winch improves efficiency and reduces the manpower required for setup.

Conclusion

Efficient, safe, and compliant waste disposal is vital for productive construction sites. Construction trash chute systems are essential tools that modern architecture cannot afford to overlook. With the right system, like those from HodChutes, project managers can ensure safer working conditions, faster debris movement, and regulatory compliance.