Home & Decor Blogs: DIY, Interior Design & Lifestyle Ideas

Oil Tank Removal Costs, Risks, and Why You Shouldn’t Do It Yourself

You’re cleaning out the basement. Moving boxes. Maybe finally getting around to that renovation you’ve been talking about for three years. And there it is — a steel cylinder shoved against the wall, behind the stairs, half-hidden by junk nobody’s touched since the early 2000s.

An oil tank.

The first thought is always the same. It’s just a metal box. Grab a buddy, rent a dolly, haul it out. How hard could it be?

Harder than you think. And riskier. And more expensive if you get it wrong.

What You’re Actually Dealing With

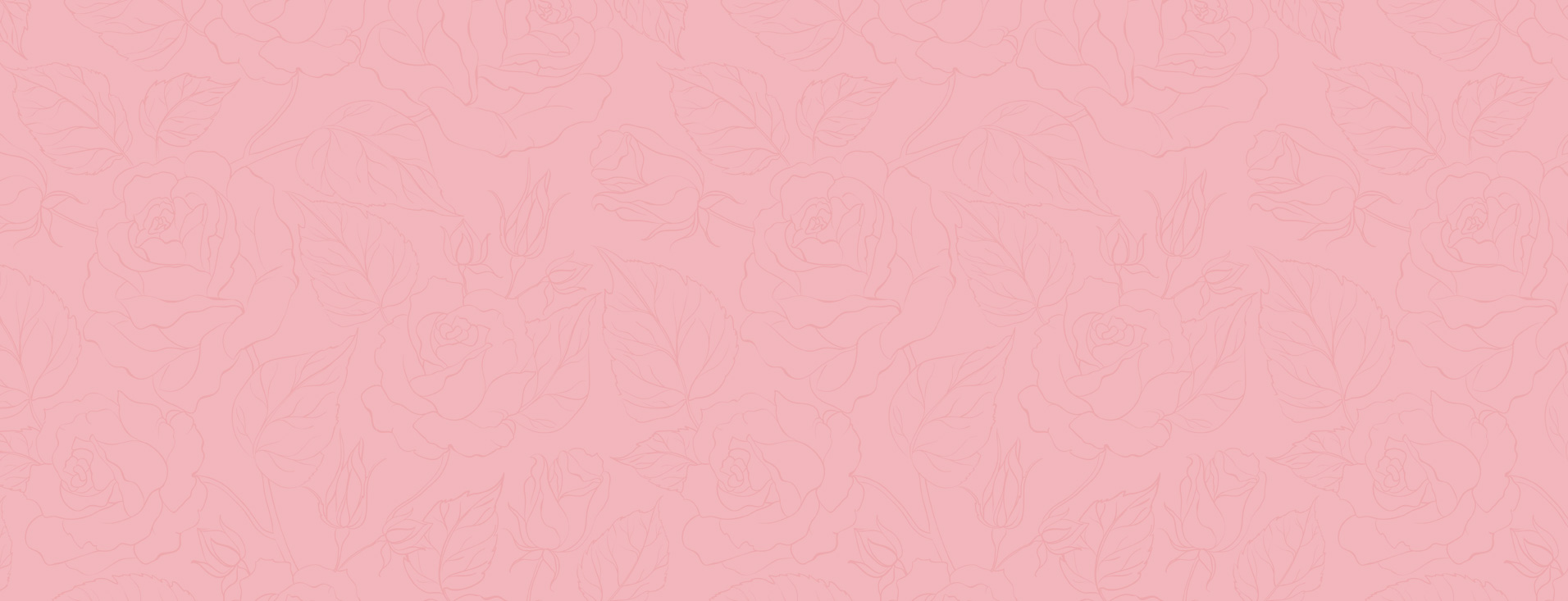

Most basement oil tanks are 275-gallon steel units. They weigh around 250 pounds empty. Underground tanks are bigger and heavier. These things have been sitting in the same spot for decades. The house has literally settled around them.

Here’s what matters — even a tank that hasn’t been used in years still has stuff inside it.

- Residual oil and sludge at the bottom. Water vapor condenses over time, mixes with rust particles, and forms a thick slurry that counts as hazardous material.

- Fuel vapors trapped inside the shell. A tank can look bone dry and still hold enough vapor to cause serious problems in an enclosed space.

- Corroded steel that’s been weakening silently for years. What looks solid can crumble the second you apply force.

The typical indoor basement tank lasts 15 to 25 years. Outdoor above-ground tanks push maybe 10 to 15 years. Underground tanks corrode in ways you can’t see at all, and by the time you notice a problem, the soil underneath may already be contaminated.

If your tank falls anywhere near these age ranges and hasn’t been inspected, you’re not looking at a weekend project. You’re looking at a professional job.

What DIY Videos Don’t Tell You About Safety

Gaseous Fuel in an Airtight Basement

Oil vapor is heavier than air. They gather in low spots — the floor of your basement, your sump pit, the area behind the boiler. In a sealed basement with not enough ventilation, these vapors can reach concentrations that may be genuinely dangerous.

You’re working down in a furnace, or next to a water heater, or electrical panels, which are an ignition source. One little spark in the wrong place and you have a situation that goes from “weekend project” to emergency response in seconds.

This isn’t theoretical. A homeowner and an electrician in Massachusetts were each hospitalized with severe burns after oil-burning equipment exploded in a basement where they were working. They were firing test shots; they weren’t even taking a tank off. Simply existing in proximity to fuel equipment was sufficient.

Rust That Doesn’t Warn You

Steel doesn’t rust evenly. It eats through in patches. You’ll snatch what appears to be a good edge, and the entire section peels off. Of course, there’s sludge or residual oil underneath — and for sure fuel on the floor and fumes in the room.

And it is even worse if you don’t know what you’re cutting into. Metal-on-metal contact can spark. When you section a tank, weight distribution changes — so the pieces shift around in unexpected ways. A 250-pound tank sliced in half doesn’t turn into two manageable 125-pound slabs. It turns into two oily slabs of awkwardness that are leaning away from each other.

Spills That Sink, Not Sit

Oil on a basement floor doesn’t just pool and wait for you to mop it. It soaks into concrete. It seeps into cracks. For months after, you smell it. And if it gets to dirt beneath or around your foundation, you’ve just caused a contamination event in the environment that’s on you.

In Massachusetts, one delivery driver mistakenly pumped 385 gallons of heating oil into a basement that had no tank at all. Six people were displaced. The state Department of Environmental Protection began an investigation. A remediation specialist said there’s no simple fix for the issue when oil saturates concrete — it can require an extensive professional cleanup.

That was a professional accident. Now, picture what a homegrown failure looks like.

What the Law Actually Says

This is where most DIY plans fall apart — not at the physical work, but at the paperwork and legal requirements most people don’t even know exist.

Federal Numbers That Should Get Your Attention

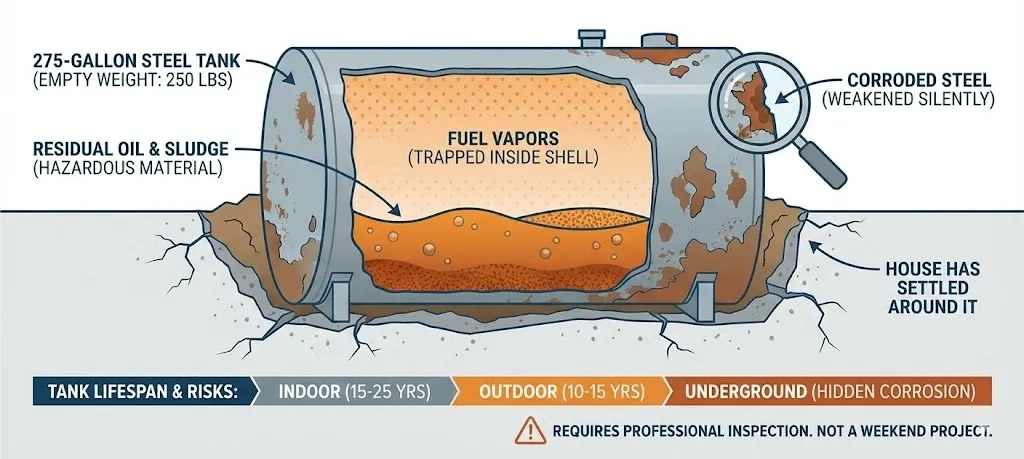

The EPA tracks underground storage tanks across the country. The numbers are staggering.

- Over 553,000 active underground storage tanks currently hold petroleum or hazardous substances nationwide

- More than 581,000 confirmed releases from underground tanks have been documented as of September 2025

- Roughly 54,000 contaminated sites are still waiting for cleanup

- About 138 million people — 41% of the U.S. population — live within one mile of an open underground tank release site

- Nearly half of all Americans rely on groundwater for drinking water. Leaking tanks are one of the most common sources of groundwater contamination

A single pinhole-sized leak in an underground tank can release 400 gallons of fuel per year into the surrounding soil. And roughly 60% of all underground storage tanks have experienced at least one leak.

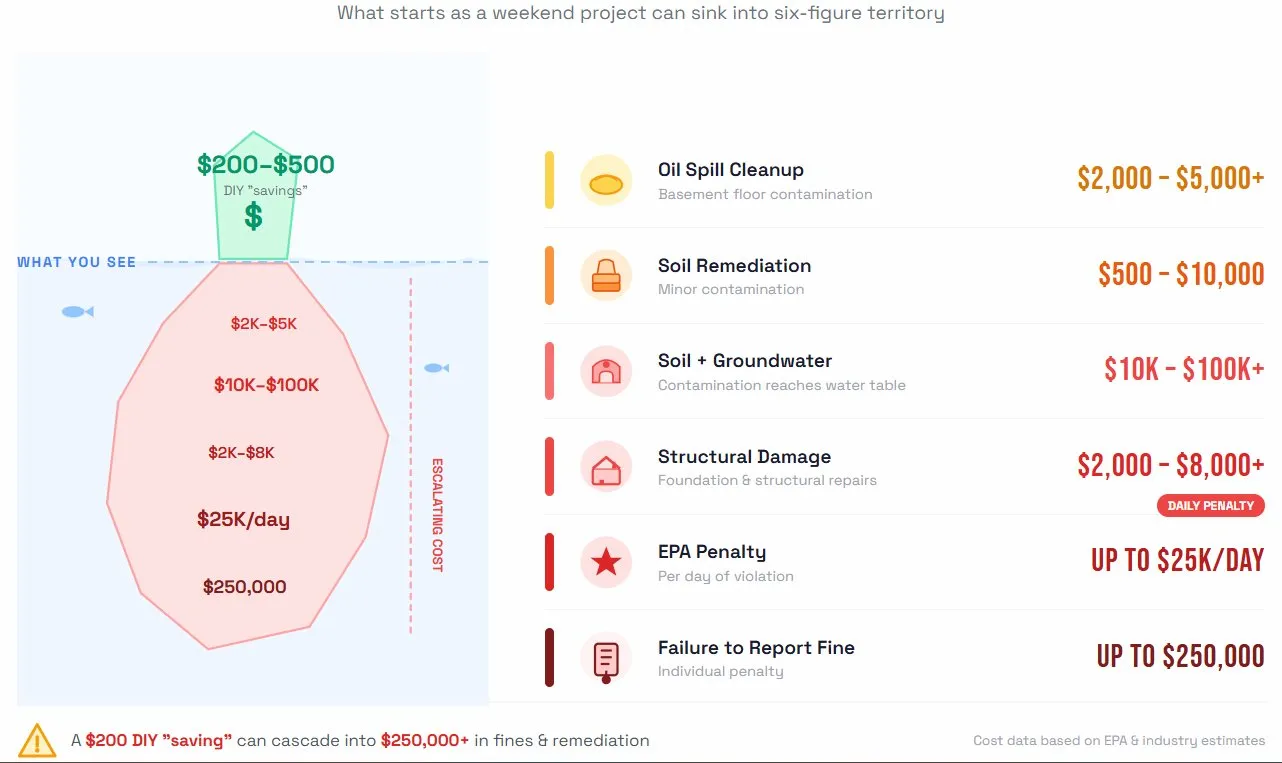

Penalties Are Not Small

Under the Oil Pollution Act and Clean Water Act, the consequences for oil contamination include:

- Civil penalties of up to $25,000 per day of violation

- $1,000 per barrel of oil discharged

- Failure to report a spill to the appropriate federal agency carries fines up to $250,000 for individuals and $500,000 for organizations

- Prison terms of up to 5 years for failure to report, and up to 15 years for more serious violations

- On top of all that, the responsible party pays for cleanup, which is a separate cost entirely

- The local fire marshal has to be notified, and in some towns, physically present during removal and soil sampling

- The contractor needs proper state registration and a minimum of $1,000,000 in liability insurance

Note: If oil has leaked, a contractor with a hazardous waste license from the state environmental agency handles remediation. Piping work requires a licensed plumber.

DIY removal doesn’t exempt you from any of this. You still need permits. You still need proper disposal. You still face the same penalties if something goes wrong. The difference is that, without a licensed contractor, you’re carrying all the liability yourself.

The Hidden Cost of “Saving Money” With DIY

The math looks tempting on the surface. Professional removal costs money. Doing it yourself costs a weekend. But that calculation only works if nothing goes wrong. And with oil tanks, things go wrong more often than they don’t.

What Professional Removal Actually Costs

| Job | Typical Range |

| Above-ground tank removal | $300 – $1,000 |

| Basement or underground removal | $1,000 – $3,000+ |

| Soil testing (above-ground) | ~$300 |

| Soil testing (underground) | ~$500 |

| Permits | $30 – $160 |

| New replacement tank + installation | $2,000 – $4,000 |

The national average for a straightforward removal is around $1,357. Not nothing, but manageable.

What DIY Gone Wrong Actually Costs

The gap between planned professional removal and unplanned DIY disaster isn’t a few hundred dollars. It’s potentially tens of thousands.

Your Insurance Won’t Bail You Out

This catches people off guard more than anything. Standard homeowner’s insurance almost universally excludes oil tank leaks and the resulting soil or groundwater contamination. Whether the tank was active or sitting dormant for twenty years, if it leaks, cleanup comes out of your pocket.

Some insurers offer a pollution liability rider, but it’s not standard. Others won’t insure a property at all if there’s an underground tank, or they’ll require proof of removal before writing a policy.

Property Sales Grind to a Halt

During a home sale, an undocumented or improperly handled oil tank creates a chain reaction:

- The buyer’s insurance company won’t write a policy with the tank in place

- Buyer can’t close without insurance

- Sales stall until someone deals with the tank

- Discovery during inspection gives the buyer leverage to renegotiate or walk

Homeowners have purchased properties with “properly decommissioned” tanks — municipality-approved, paperwork in order — only to discover during resale that soil testing was never done and contamination existed all along. The cleanup responsibility landed on the new owner.

A professional removal with clean soil results and proper documentation is a one-time expense. An unplanned discovery with contamination is a financial spiral.

What Professional Removal Actually Looks Like

The process is more involved than most people expect, which is exactly why it’s not suited for a Saturday afternoon.

Oil extraction. Crews pump out remaining usable fuel with explosion-proof transfer pumps. That oil doesn’t go to waste — it gets filtered and reused. Some contractors will credit you for the salvageable fuel or deduct it from the bill. Worth asking about.

Sludge removal. They cut an opening, scrape out the hazardous sludge by hand into buckets, and transfer it to sealed drums. This material requires special disposal.

Pipe disconnection. Fuel lines and vent pipes get cut from the foundation. Holes through concrete get patched. Through wood walls, sealed and repaired.

Tank extraction. If the doorway allows, the tank comes out whole. If not, it gets sectioned into pieces in a controlled sequence — planned cuts, managed weight distribution, protected floors and walls. Everything goes to an approved disposal facility.

Soil testing. Especially critical for underground or long-sitting tanks. Lab results take roughly two weeks. If contamination shows up, remediation follows.

Companies like Envirotech, which have been handling oil tank in basement jobs for over 28 years, use forced ventilation, protective gear, and controlled draining before anything gets moved. Every step happens in a planned sequence designed to keep fumes contained and oil off your floor.

DIY vs. Professional — The Honest Scorecard

Here’s a straight comparison across the things that actually matter:

| Factor | DIY | Professional |

| Physical safety | High risk — vapors, heavy lifting, confined space | Controlled — ventilation, gear, trained crews |

| Legal compliance | Cracked floors, damaged walls, and gouged concrete | Contractor handles permits and documentation |

| Contamination risk | One mistake puts oil in concrete or soil | Controlled draining and containment protocols |

| Structural damage | Capped at the contractor’s service cost | Exit paths measured, surfaces protected |

| Insurance coverage | None — standard policies exclude oil tank incidents | Contractor carries liability + pollution coverage |

| Disposal | You figure out hazmat recycling yourself | Contractor has certified facility access |

| Soil testing | You arrange and pay separately, if you remember | Often bundled into the job |

| Documentation for resale | Whatever you can piece together | Professional paperwork, lab results, permits |

| Timeline | “One weekend” that often stretches into weeks | One to two days for standard removal |

| Total risk exposure | Unlimited personal liability | Capped at contractor’s service cost |

The only column where DIY wins is the upfront sticker price. And that advantage disappears the moment something goes sideways.

If You’re Replacing, Not Just Removing

New tanks are built to better standards than whatever’s been sitting in your basement since the ’80s. But installation still has to be done right, or you’re just trading one problem for another.

What modern replacement tanks offer:

- Double-wall construction for built-in leak containment

- Leak detection systems that catch problems before they spread

- UV-resistant coatings for outdoor installations

- Condensation-reducing designs that slow down the interior rusting that killed your old tank

Professional installers work to NFPA codes. The tank needs clearance for future inspection. Vent pipes need proper airflow. Shut-off valves have to be accessible. Spill containment at the fill point is required. Miss any of these, and you’re looking at a failed inspection or a system that quietly causes problems for years.

Timing tip: Spring and early autumn are your best windows. The heating system needs to stay off for six hours or more during installation. Doing that in January means a cold house, frozen pipe risk, and a miserable experience. Plan if you can.

If you currently have an underground tank, every environmental professional will tell you the same thing: replace it with an above-ground model. Underground tanks corrode invisibly, leaks go undetected for years, and cleanup costs reach tens of thousands.

One More Thing

Research published in the American Economic Journal found that living near a leaking underground storage tank increased the probability of low birthweight in newborns by 8.7% and preterm birth by 7.4%. Once the leaking tanks were removed, infant health improved sharply.

This isn’t just about your basement or your property value. Leaking oil tanks removal affects the people around them — neighbors, children, and the water supply that serves your whole area.

Professional removal runs a few thousand dollars and takes a day or two. A contamination cleanup, a stalled property sale, an insurance dispute, structural damage from a botched attempt, or a health issue nobody saw coming — any one of those can cost ten times more and drag on for months.

If there’s an old oil tank in your basement or buried in your yard, deal with it on your terms. Not on someone else’s.